Real Info About How To Build Robot Arm

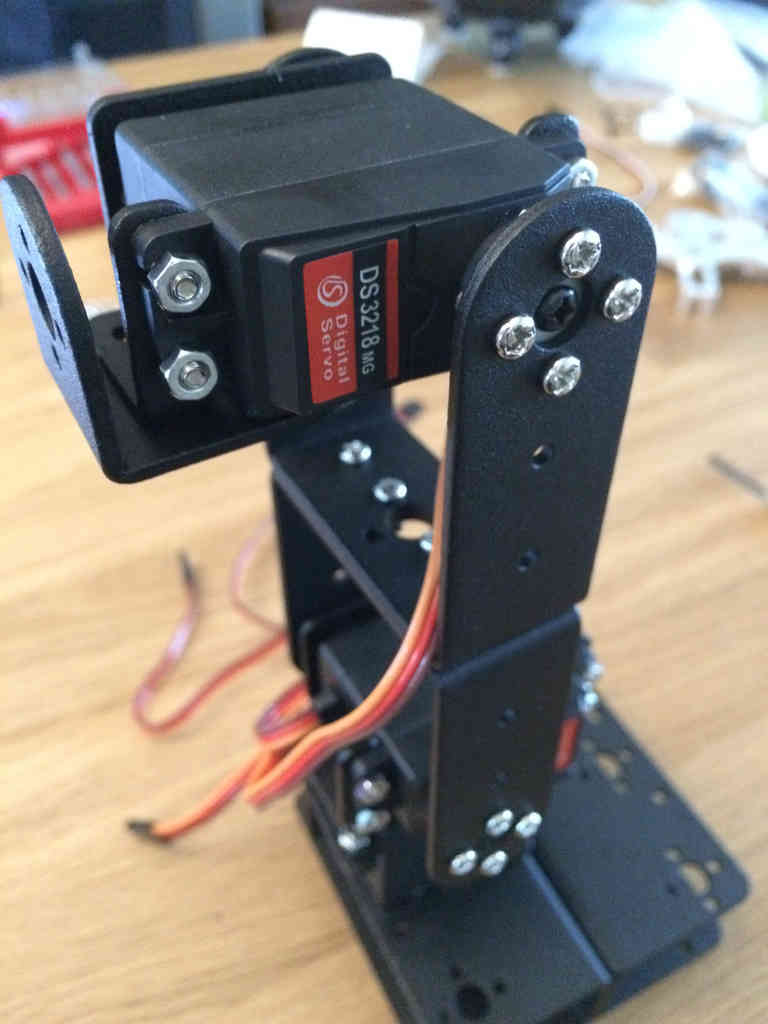

Next, attach the servo horn to the left lower arm.

How to build robot arm. Feb 22, 2024, 6:00 am pst. 1 x 12v dc power supply 4. Robotics is a growing field with many applications in both industry and research.

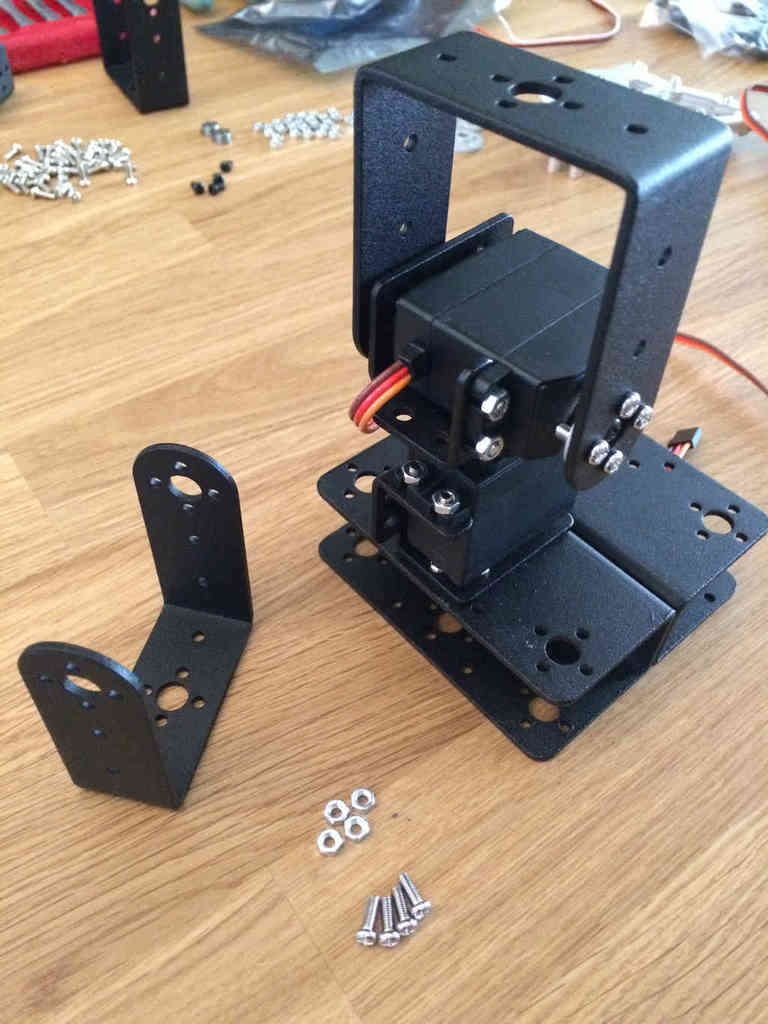

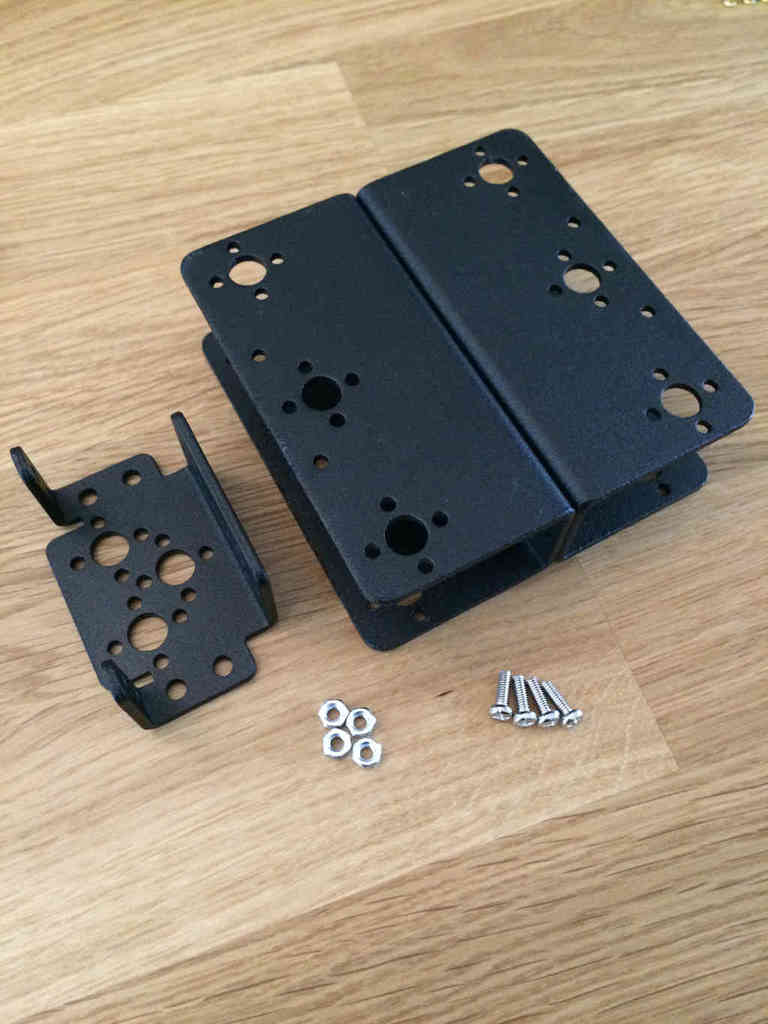

Before we can start we need to get some part´s and plan´s. Before you put tools to work, it’s imperative to start with a comprehensive plan. In the end, you’ll have.

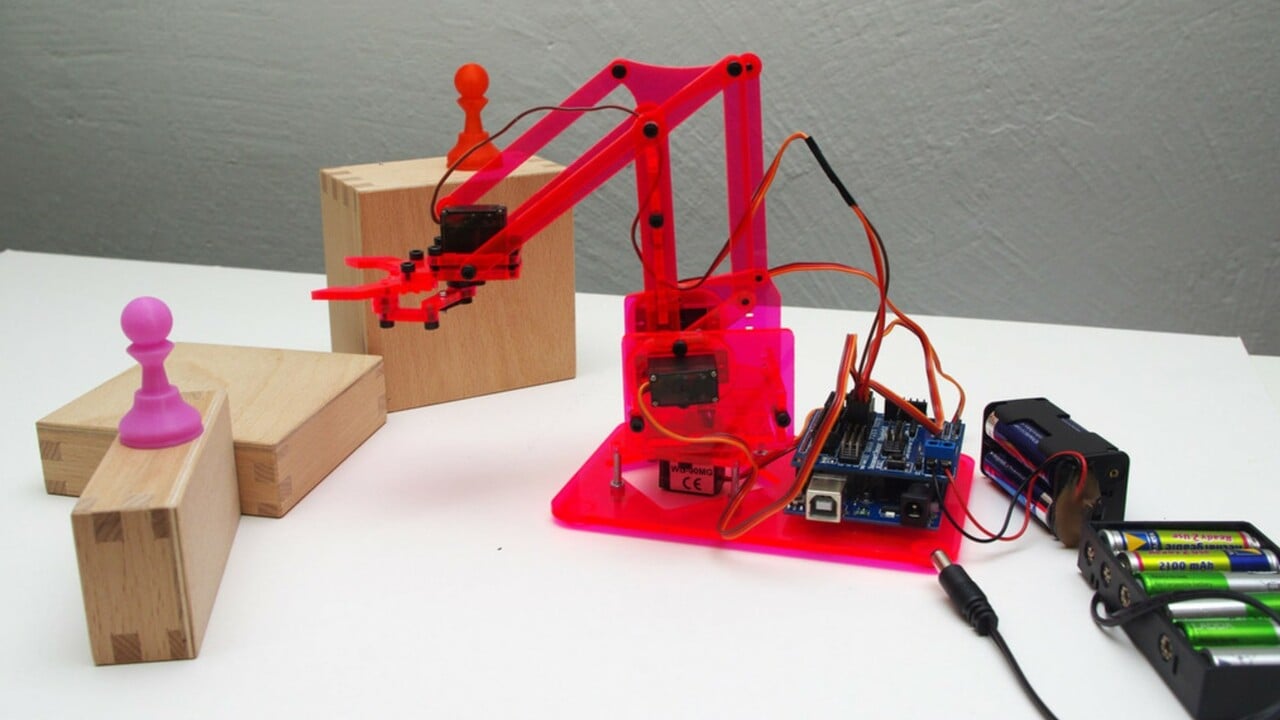

Regarding this robot arm, dejan made a comment about bearings not fitting (due to plastic shrinking when cooling). How to build a robot arm from recycled materials blog postcircuito.io teamjun 25, 2018 robot arms are one of the most popular diy projects you’ll find online. Home arduino how to build a simple arduino robotic arm [diy] march 11, 2017 by anusha robotic arm is one of the popular concepts in the robotic.

Make sure that the servo shaft is nearer to the end. This video will take you through. Set the servo angle to 45° as done before using the evive’s firmware.

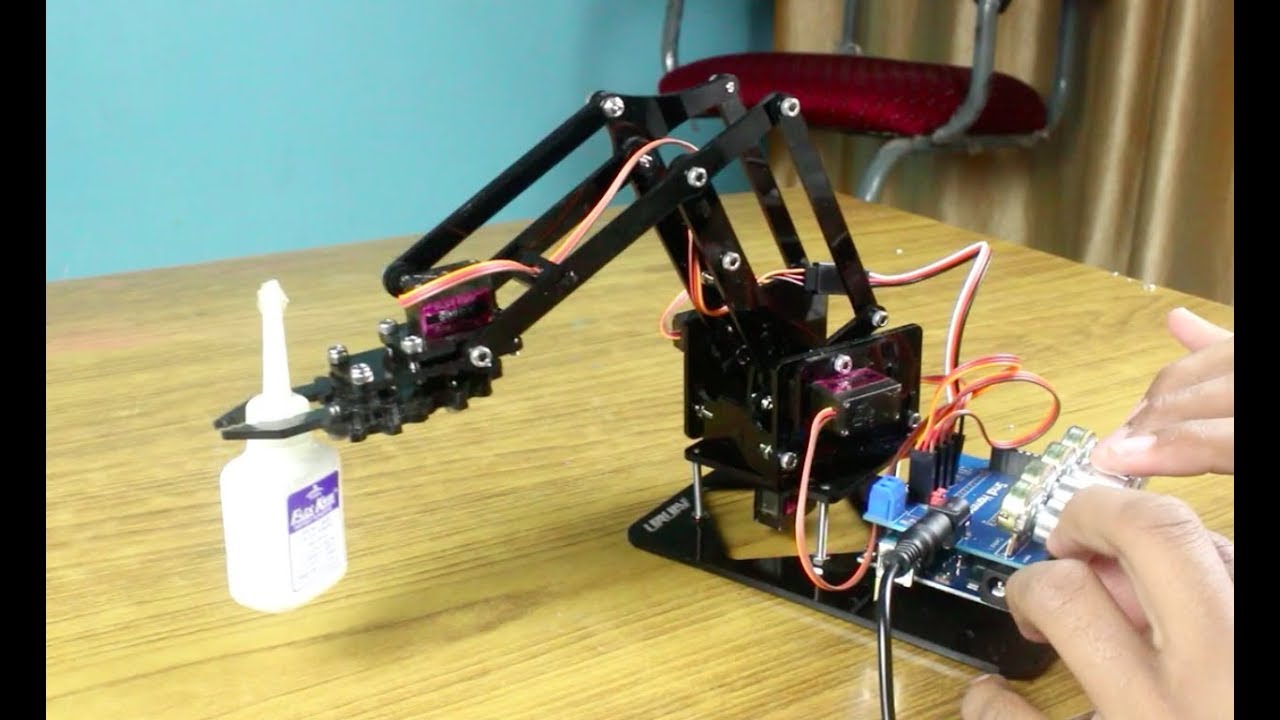

The process contrary to what most people may be led to believe, making a simple robotic arm is not that complicated, and it can be done with anyone who has a good grasp of. Next, connect the signal wires i.e yellow or. Well, it’s time to learn.

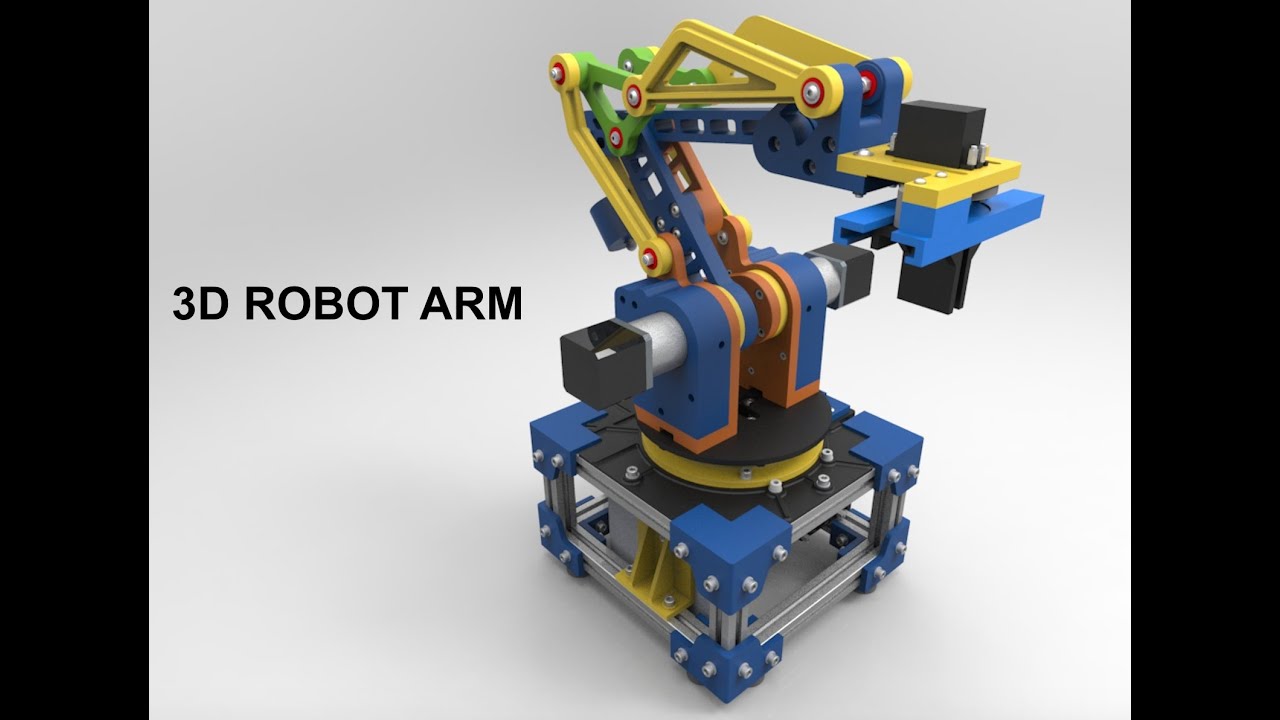

In this detailed step by step tutorial we will go through the process of building a robotic arm using a 3d printer, nema stepper motors,. 1 x motor controller 3. And by mimicking natural human gestures such as a pinch, or a wrist.

First connect all the servos in parallel to the power supply. Learning to build a robot arm will teach you how to breadboard a circuit, how to program your arduino, and how to work with moving parts. Sketch out your robot arm — considering its purpose, size, and.

9.2k 443k views 9 months ago united states i made an arduino based robotic arm with a unique control system for under $60! From sourcing the equipment to programming your robot to move, you’ll be guided. Oke let´s start building on this thing.

(the red wire to +5v and black or brown wire to gnd). 1 x 6v dc motor 2. You must make sure that the motor you choose can not only support the weight of the robot arm, but also what the robot arm will carry (the blue ball in the image below).